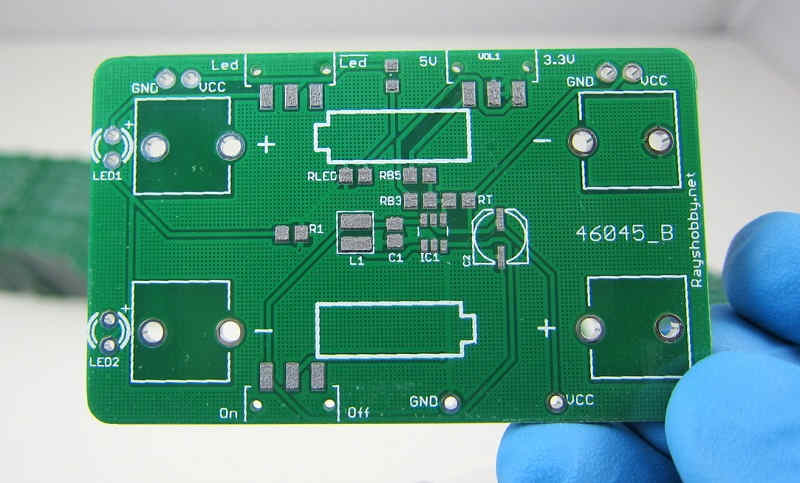

When it comes to PCB design, many designers aim to add a panel, but this is not always easy. The good news is that there are some guidelines for PCB panelization that PCB designers can easily follow as long as they have the basic knowledge and a good piece of software to aid them.

Here, we are going to talk you through some of these PCB panelization guidelines so keep reading if you’d like to find out more.

Processing Edge

The first guideline for PCB panelization involves the processing edge and you would add this to the panel. When it comes to small boards, you need to make sure that you add a processing edge to make it bigger or create your own Panelization of boards. This is because certain machinery cannot process any sort of PCBs with less than a 50.8.mm conveyor width. Make sure that when the length of the PCB is shorter than this that you add the processing edges.

If you are using an odd-form board then you will need to approach this in a slightly different way. This is because, with odd-form boards, you don’t necessarily have two parallel edges for processing, so you need to add the processing edges somehow.

This can often mean that designs are very interesting and complex as they need to be depanelized. If you are going to be using an odd-form board, take a look at some of the guidelines below which could help you to go ahead with the Panelization.

Board-Array Dimensions

When you are designing your PCB panelization, you need to make sure that you are securing the benefits of running multiple boards. You should also limit the size of the panelization in order to prevent any sort of weakness in the PCB.

If there is a weakness, you will find that the PCB will cause a vibration in the machine and you could cause some serious problems.

Panelization Methods

When you are choosing your Panelization method, you need to make sure that you are considering all of the options. You might find that the best option for you is actually a combination of some of the methods in order to make the PCB Panelization secure and provide a viable breakout method. If you want to increase the strength of the board, you need to increase the board count that you’ll find on the fabricator’s panel.

Summary

If you are a PCB designer, then you need to make sure that you are using the best software out there right now and that you are equipped with the knowledge that lets you design a quality board. When it comes to PCB Panelization, you should make sure that you are following the guidelines that we have discussed in this article.

Make sure that you design your project with these guidelines in mind and you should be able to come out the other side with a great PCB and a working product.